Last Monday we took delivery of our new dinghy. We bought an AB ALX 11 from Guyer Boatworks in Bellingham. Center console, aluminum hull, plenty of storage…all things we did not have on our old Zodiac that will certainly make this one heavier but way more comfortable. (This particular AB ALX 11 was actually a 2017 model that Guyer Boatworks had used in boat shows over the past two years, so we got a bit of a deal on it!) We had them outfit the AB with a Tohatsu 30HP outboard with power tilt and electric start, a removable downrigger mount (not shown in photo), and also the small Garmin chartplotter that we had on our Zodiac (mounted/hardwired onto the center console). This little baby is a seriously fun and capable tender for Airship, and we had a great experience working with Guyer Boatworks.

We took our new dinghy out for some “testing” later that afternoon and were very impressed. The ride is super smooth, dry (!!!), and quiet. We are for sure going to have a blast with it in BC and Alaska this summer.

On Wednesday, Josh from Olsson Manufacturing came up and installed the new dinghy on our Roskelley Olsson davit. Now, with a push of a button, the davit lowers the dinghy into the water and 30 seconds later we’re ready to go exploring. LOVE this davit, and Josh gave us superb service.

To bring the dinghy back up, simply attach the two bridles to the lifting arms, get out, push the button to raise the dinghy out of the water, then secure it with its safety cable.

The dinghy sits high enough so that following seas won’t touch it for the most part, and with this setup, the swim ladder on the swim step is usable even with the dinghy on the stern! (That’s the ladder, tucked away on the lower left, under the swim step.)

With the dinghy up, we have great access on and off the boat from the port side of the cockpit:

The next project was a small one but a good one: we replaced all the non-slip tape on the boat. There are strips at each pilothouse door, one strip on each side of the cockpit where you might climb or step over the transom, and two wide strips at the back of the cockpit. They were all starting to crack and peel up on the edges, which is not a big deal but definitely contributes to a boat having a slightly “aged” feel. You might not notice it at all, but new strips made a huge difference. I bought a roll of two-inch wide material, and five feet of four-inch wide material, and then carefully removed the old pieces so that I could trace the rounded corner shapes. Removing the old adhesive from the gelcoat was the hardest part of this job.

Next, we attacked what we know has been an issue for some other Nordic Tugs of similar age: the seam where the upper deck meets the pilothouse. As that caulking ages and cracks, this seam becomes an area where water can sneak in and seep into the balsa core of the upper deck. This is not where you want water, and if it gets in, there’s nowhere for it to drain or vent.

I bought some caulk removal tools (which I ended up eventually ditching in exchange for my trusty utility knife) and went to work getting as much caulk out as possible. I then taped the outside edges and went to work with some UV Sikaflex and another round/corner tool. The port side of the deck has this two-step ladder (in photo below) up to the flybridge, and hard as I tried I could not get one clean left-to-right sweep that wasn’t interrupted by some part of the ladder. I even tried putting my upper body through/between the two steps to see if an arm could reach all the way left to right, but no joy. It still came out pretty clean, in spite of the obstacle:

The starboard side has a nice clean caulk line, made with one sweep of the arm!

On Thursday evening, Tony (of Marine Systems Northwest in LaConner) came by to install our flybridge electronics:

It was late by the time we finished up with the new chart plotter and autopilot, so I brought up the Fatboy LED lamp for some ambiance.

New Garmin chartplotter on the right, and below that, new VHF handset and autopilot

Friends from Portland (Becki and Stephen) were driving up on Friday for some San Juan cruising and to try out our guest room, but before we met them at Airship we drove over to LaConner to see our friend Ralph’s new boat, Jester (a 2014 Nordic Tug 39) go back into the water after being trucked out here from Florida. It’s been out of the water (getting new electronics, a stern davit like ours, and a handful of other upgrades) since it arrived, and Ralph was pretty happy to have it floating again:

Spring is finally here, and the weather has been amazing this week. I hear the tulips are a little late this year, but the daffodils are going strong!

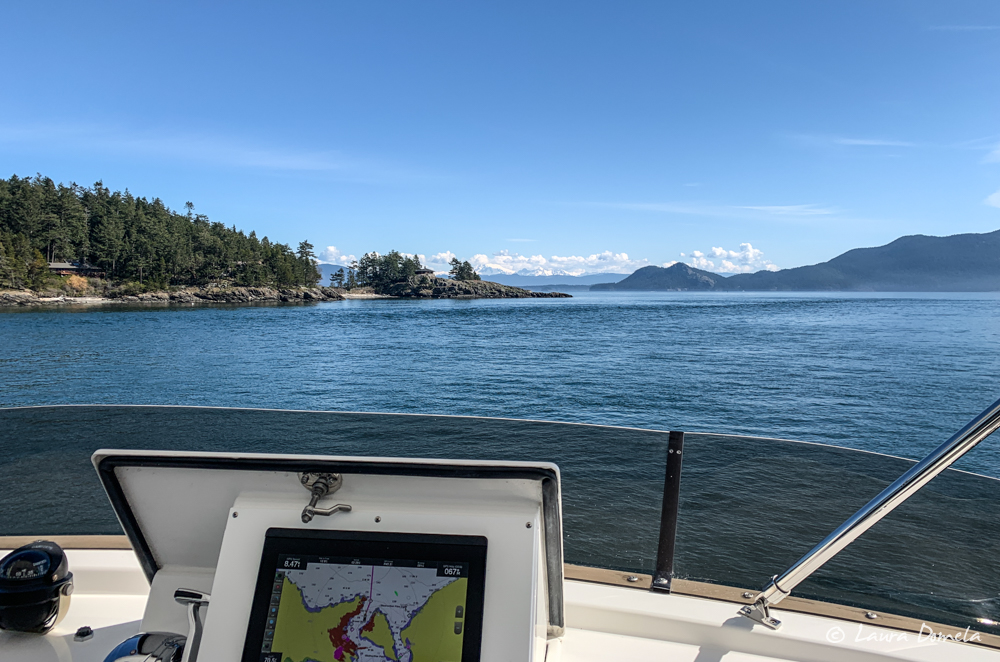

We were happy to have the flybridge electronics up and working this weekend–we enjoyed two days of cruising from up top!

We headed first to Echo Bay on Sucia Island, where we explored surrounding coves and islands by dinghy, made fish tacos for dinner (with the last piece of halibut from the previous summer’s fishing), and enjoyed a beautiful sunset followed by a clear, star-filled night sky.

We took some shots of Airship in the glassy water while out in the dinghy:

Sunset in Echo Bay:

On Saturday morning we awoke to more calm water, sunshine, and blue skies:

This is a steam plume from Sherman crater on Mt Baker, often visible on clear crisp days like today:

Before breakfast, we decided to take the dinghy over to Matia Island (about 3nm across) for a little hike. This seems silly, I know, since Sucia Island has our favorite hiking of all the San Juans, but we’d hiked Sucia before with Becki and Stephen and they were interested in seeing an island they hadn’t been to previously, so Matia it was!

Back on Airship we made some breakfast sandwiches and then headed around (the long way) to Rosario Resort on Orcas Island. We hadn’t visited Rosario since they rebuilt the docks. The layout isn’t much different from before, but the new metal docks are very nice.

We made it up to the mansion in time to catch the organ concert (4pm on Saturdays) and history slide show.

After touring the small history museum and walking the grounds a bit, we ate dinner in the Mansion Restaurant (very good)! So good, that we went back for brunch the next morning before cruising back to Anacortes.

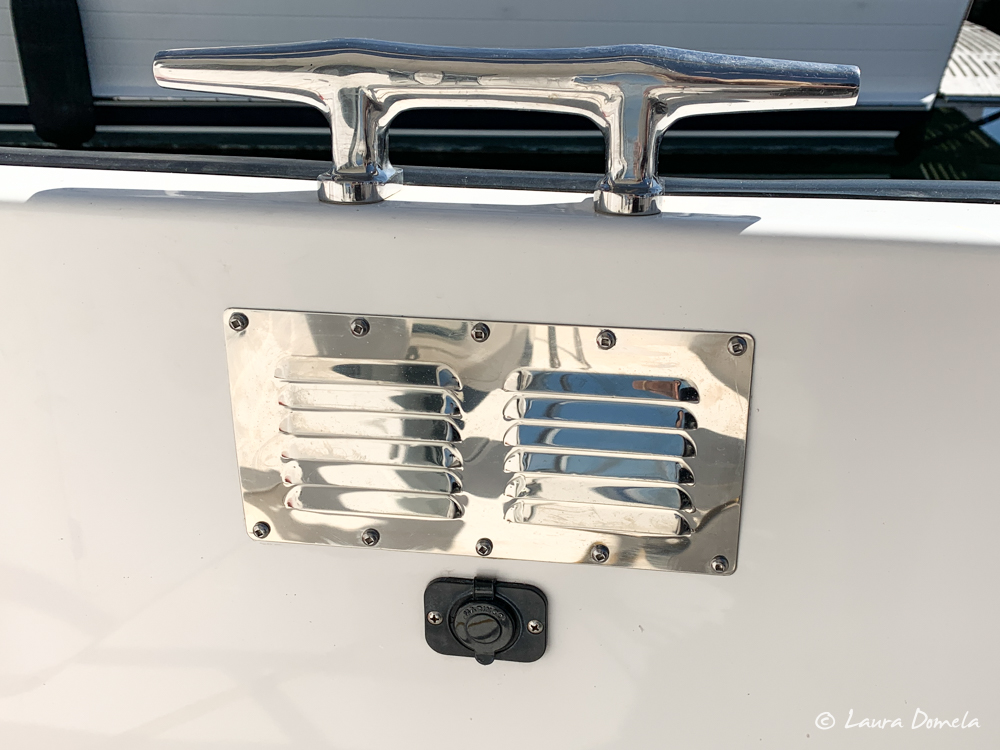

After we said goodbye to Becki and Stephen back in Anacortes, we took another trip to West Marine in order to tackle a few more boat projects. Next up: replace the painted vents in the transom (they had a little rust on ’em) with stainless vents:

And after that: the next part of the upper deck seam project involves cutting two two-inch holes through the fiberglass in the underside of upper deck (where it overhangs into the cockpit), exposing the balsa, and then covering those holes with stainless vents. This will allow the upper deck coring to breathe, hopefully getting rid of any moisture that made its way in. Thankfully, the core here felt completely dry and we neither felt nor saw a drop of anything:

Now we’ve got a nice shiny four-inch stainless vent on each side:

We removed everything out of the engine room and did an inventory of all the spare parts and tools and miscellaneous stuff, then got it all organized into labeled crates and arranged those (back into the engine room) by how often we need access to each crate. We also replaced a dead float switch in the middle bilge under the shaft seal, and did a few other small tweaks and fixes around the boat. It feels so good to have almost all of our ducks in a row as we get ready to head north this year.

Next couple of things we want to finish before heading north: install the new 11 gallon Isotemp water heater with dual heat exchangers, have the rear camera installed, and put one more GMI20 marine instrument in the master stateroom (mainly to watch depth, wind, and anchor alarm from bed).